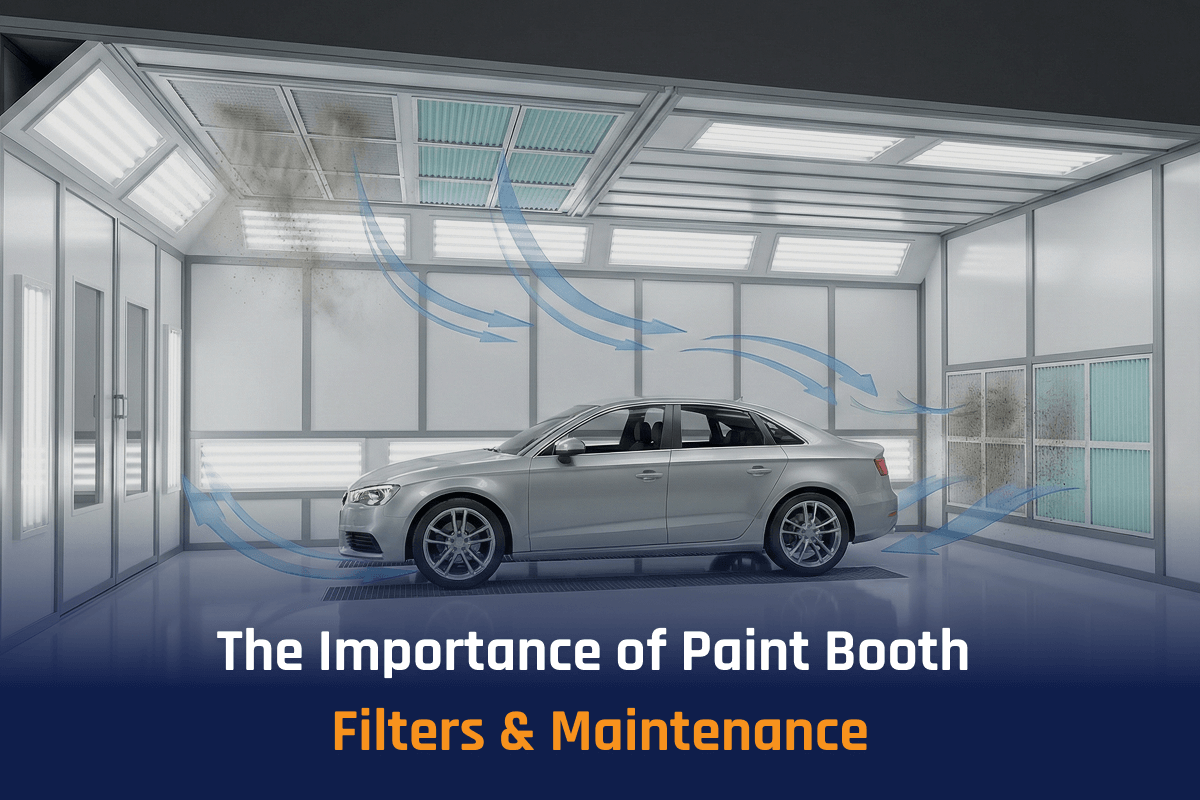

Paint booth filters are integral and complex components. They have a direct impact on finish quality and maintenance costs. These filters are designed to trap contaminants like particulates and dust, thereby maintaining the safety of the workforce. With this blog, we at Sunstar Paintbooths & Auto Equipment aim to shed light on the importance of paint filters and timely maintenance.

What are Paint Booth Filters & What is Their Function?

Paint booth filters are simply protective barriers for the system’s components. They come in different types, each designed to remove pollutants like dust and debris. Some of the 3 main types of paint booth filters:

- Air Makeup Filters: These filters serve first line of defence located in the air makeup unit. It provides pressurized air to the booth and traps large particles before they reach the air makeup unit.

- Intake Filters: These filters are internally polyester panel filters or linked panels used in downdraft and crossdraft paint booth Dallas TX, to keep contaminants away from paint coatings.

- Exhaust Filters: These filters ensure that the air leaving the booth is safe for the environment and prevent the presence of toxic chemicals in the spray paint booth.

Importance of Timely Paint Booth Filter Maintenance

At Sunstar Paintbooths & Auto Equipment, we emphasize proper maintenance of spray booths and filter system maintenance.

Fun fact: Did you know proper paint booth filter maintenance can significantly improve your finishing operations?

Regular paint booth filters and maintenance have a direct impact on paint finish quality and the safety of operations. If the paint booth filters are not properly maintained, it compromises on work environment safety, thereby endangering workforce. The following are things you can do to ensure the efficiency of paint booth filters:

Tips to Maintain Efficiency of Paint Booth Filters

- Proper Working Manometer: A high-quality filter needs at least 100 operational hours. This implies nearly 2 to 3 working weeks. A manometer allows you to see whether the filter is working loaded and when filters need to be replaced.

- Make Use of Top-quality Filters: A good quality filter goes on for a long time. High-quality filters translate to more efficiency and a long service life for filtration action.

- Compliance with Safety: Clogged filters can create flammable and explosive conditions. It is important to ensure that cleaning overloaded filters is performed and that OSHA and NFPA regulations are met.

Wrapping Up

Proper maintenance improves workplace safety, lowers operational costs and ensures high-quality paint finishes. With Sunstar Paint Booth installation, you can rely on our unwavering commitment to excellence. All our paint booths are well-equipped with proper filtration and fire suppression systems, offering an optional painting environment. Whether it is auto body shops, car dealerships, refinishing operations or auto businesses, we offer a wide range of spray paint booth solutions. Explore our range of products and request quotes.