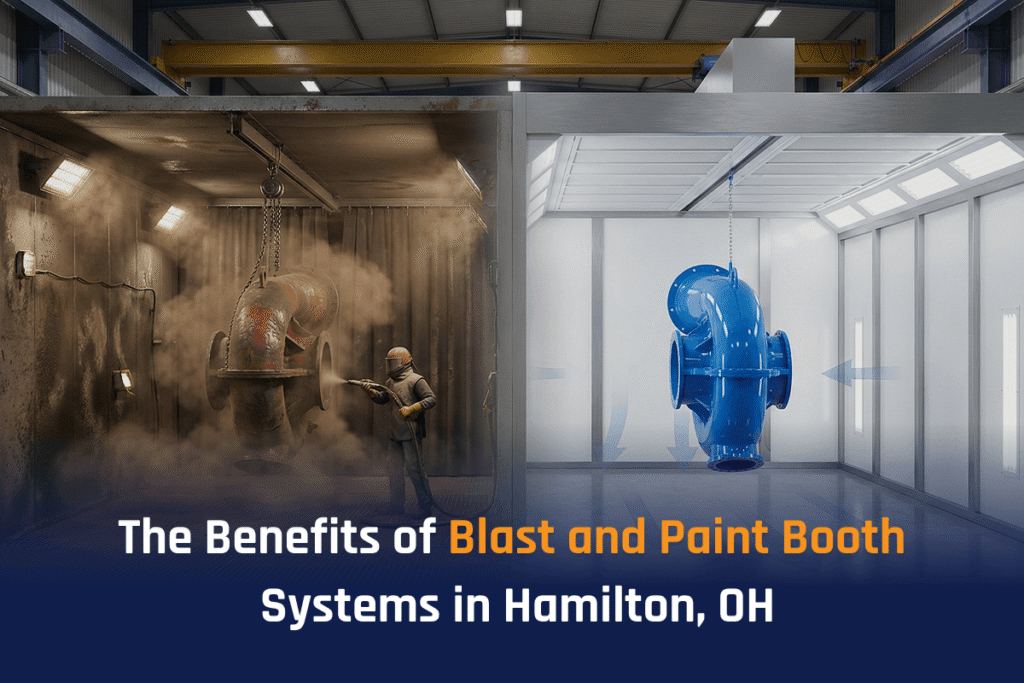

Working in a paint booth means constantly surrounding yourself with paints, chemicals, and fumes. The best way to protect the workforce from hazardous fumes is to use a reliable spray paint booth equipped with a proper ventilation system to ensure adequate airflow. It is a safety system designed to control overspraying, dust, and flammable debris. Proper ventilation is important to remove flammable vapours and maintain safe working conditions. In this blog, we understand paint booth ventilation requirements in terms of codes, airflow, and compliance to help you ensure your paint booth is well-ventilated.

Paint Booth Airflow & Code Requirements

OSHA: As per OSHA, paint booths should be designed to remove flammable contaminants and move the air towards the exhaust for proper ventilation. The system must have an independent exhaust system in place to discharge fumes. The ventilation should be functional and working at all times, and after the spraying process, the exhausted air should not be moved back into the booth.

EPA: As per EPA guidelines, filters with upto 98% capture efficiency should be installed in the paint booth Houston. The spray paint booth for automotive refinishing should be completely enclosed and have ventilation at a negative pressure or up to 0.05 inches.

Whether you are working in automotive, industrial coating, or other refinishing work, understanding these paint booth airflow code compliance is important for quality output and regulatory compliance.

Understanding Aiflow in Spray Paint Booths

Many businesses think compliance is just about clean air in a booth. The focus should be on how the air moves in the booth. The air flow should be:

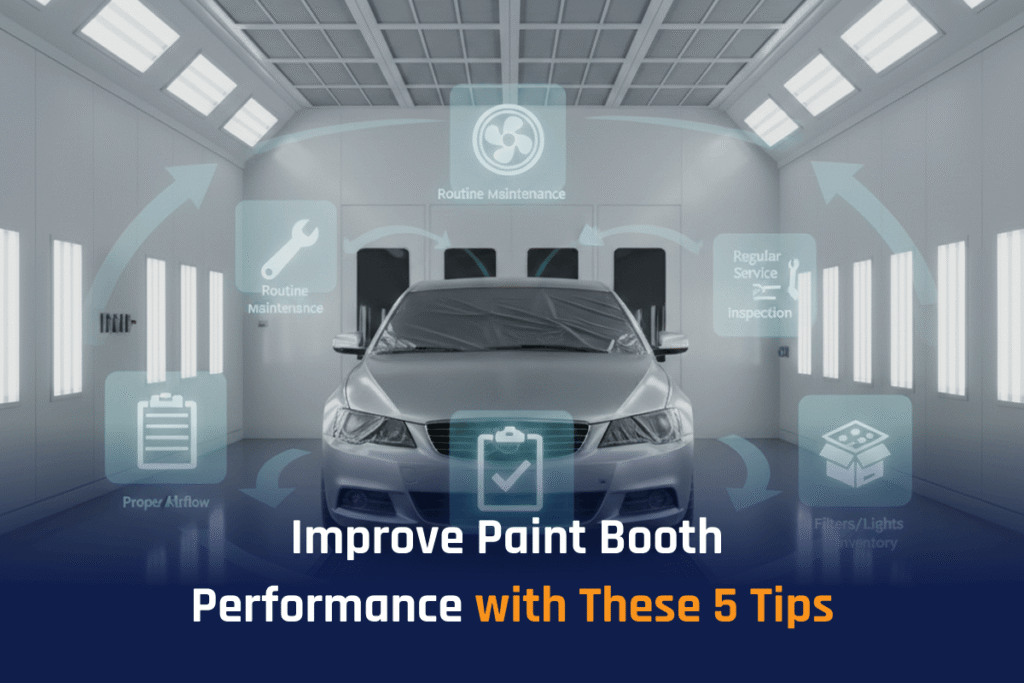

- Even Predictable Airflow: The ventilation system should pull contaminants away from the work zone and towards the exhaust in a controlled pattern. Patchy or turbulent airflow can allow overspray to escape or vapour to collect in stagnant areas.

- Minimum Required Airflow: NFPA 33 sets the minimum required airflow values to ensure contaminants are adequately diluted and removed.

- Continuous Airflow During & After Spraying: Ventilation must run throughout the paint process and long enough even afterwards to clear lingering vapour. This helps protect workers and reduce buildup.

Dedicated Exhaust is a Code Priority

- Exhaust Should Not Be Connected to Building HVAC: The paint booth exhaust should have its own separate ducting to prevent flammable vapours from entering other systems.

- No Recirculation of Contaminated Air: Re-introduction of booth exhaust air back into the building can bring overspraying and solvent vapours into the workspace.

- Safe Discharge: The exhaust should move outside and away from the doors, windows or HVAC system so the contaminants do not enter the booth.

Invest in a Paint Booth with a Proper Ventilation System

Paint booth ventilation is about more than airflow; it is about controlled, code-compliant air movement that protects people, property, and quality of finish. At Sunstar Paint Booths & Auto Equipment, we design spray paint booths with advanced airflow control and ventilation features to help you meet safety codes and achieve superior results. From downdraft to semi-downdraft systems, every booth is engineered to provide consistent airflow and dependable performance. For tailored solutions, expert installation, and support that fit your shop’s needs, choose Sunstar Paint Booth to elevate your finishing operations to the next level.

FAQs

- Why is ventilation required in a paint booth?

Ventilation is required to remove hazardous overspray, dust, and flammable vapours from the booth so they don’t build up to dangerous levels. This protects workers from inhaling harmful substances and reduces fire and explosion risks.

- What airflow speed is required?

Ventilation systems are typically designed so that the air velocity into the booth through openings is at least 100 feet per minute on average, although requirements can vary depending on the type of spraying operation

- What happens if the ventilation system fails or is blocked?

If filters are clogged or fans are worn, airflow can drop. Reduced airflow means vapours may collect, increasing exposure and fire risks. That’s why proper maintenance and documentation are crucial for safety and compliance

- Is ventilation required even for water-based paints?

Yes. While water-based paints may not be flammable, they can still release harmful fumes or particles. Ventilation is required to protect workers from health hazards and maintain a safe workspace.