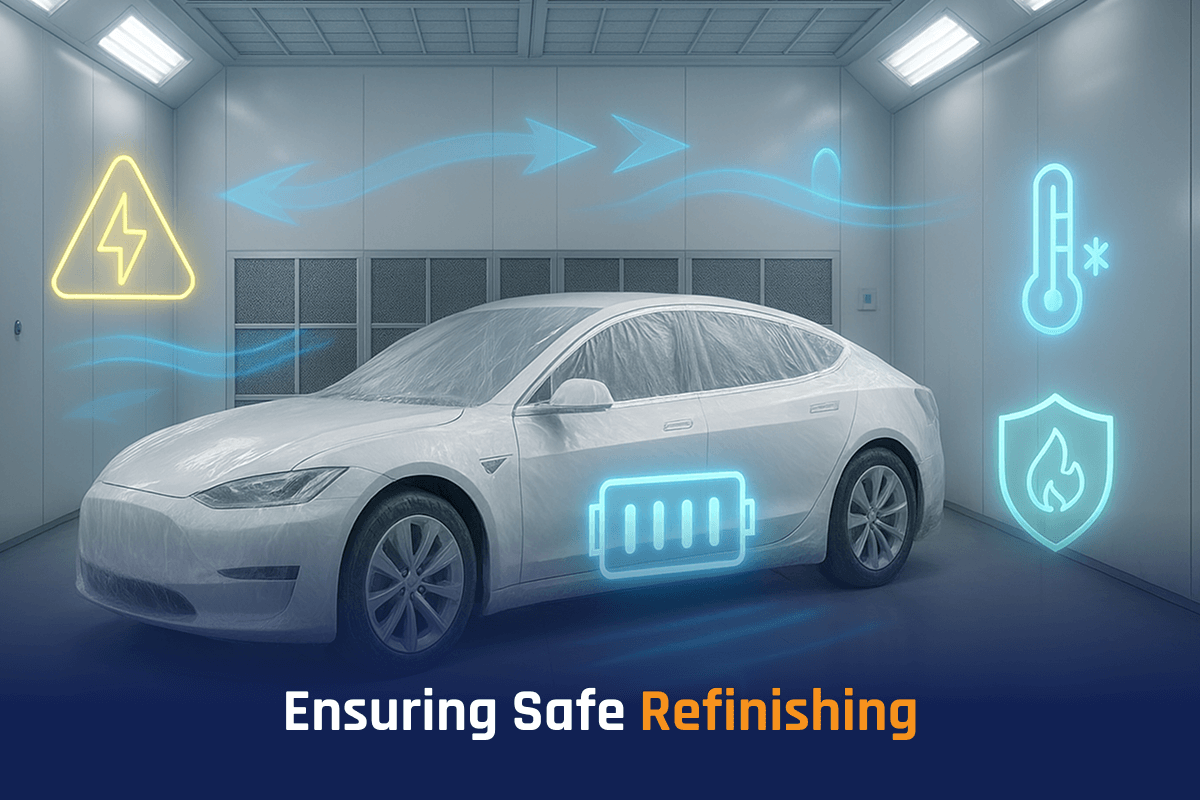

The automotive paint industry has drastically changed with the emergence of electric & hybrid vehicles. However, it is crucial to adapt to high-voltage automotive painting to ensure safety, efficiency, and high-quality finishing results. At Sunstar Paintbooths & Auto Equipment, we deliver top-notch paint booths for auto body shops, automotive businesses, car dealers and other businesses. In this blog, we discuss the best practices for high-voltage vehicle safety standards to ensure safety and high-quality refinishing results.

Risk Associated with Painting Electric & Hybrid Vehicles

EV and hybrid vehicles are backed by high-voltage electrical systems. These batteries pose a significant risk if not handled during painting or refinishing processes. This is because extreme heat and humidity can damage the electrical high-voltage components, including batteries. Excessive heat can impact battery integrity, compromising safety and performance. This is why it is best to opt for specialized refinishing practices to ensure safety and optimal painting results.

Best Tips for High-Voltage Vehicle Painting

● Ensure Safety in Paint Booths

When painting with high-voltage vehicles, the priority lies in safety. Begin by disconnecting the batteries to ensure the critical components, including high-voltage systems and batteries, are within the safe temperature ranges.

● Proper Ventilation

For refinishing projects, ensure proper ventilation and airflow. The paint booth and auto equipment should have proper airflow so the heat generated can dissipate, prevent overheating and reduce the risk of accidents.

● Opt for Faster Production

Using faster production is one of the best practices for electric & hybrid vehicles. Quick-drying finishing painting can be cured at low temperatures, preventing EV’s exposure to heat.

● Fire Safety

When it comes to working with high-voltage vehicles, fire safety considerations are paramount. The lithium batteries are extremely prone to combustion, which could pose a major fire hazard. Opt for a fire suppression system to address these challenges, protecting workforce safety and facility damage.

Adapt Your Paint Booth for Electric Vehicles with Sunstar Paintbooths

With the growth of electric vehicles, it is crucial to prepare your paint booth for EVs. By optimizing your facility for high-voltage vehicles allows you to position your business in the electric painting industry. At Sunstar Paintbooths & Auto Equipment, our paint booths are designed to meet the demands of the high-voltage industry. Our comprehensive range of paint booth solutions includes full downdraft spray paint booths, semi downdraft spray paint booth, side downdraft spray paint booths, customized paint booths, and much more. Contact us to partner for high-voltage optimized paint booth solutions.