Paint booth airflow plays an important role in spray paint performance for different applications. The proper measurement of airflow in a paint booth is crucial to maintain the finish quality, safeguarding workforce health & safety while reducing operating costs. So when businesses are installing paint booths, proper airflow should be top priority. In this blog, we explore different ways to measure paint booth airflow for high-quality results and workplace safety.

Why Measure Paint Booth Airflow?

Understanding how to measure paint booth airflow can help determine if the booth is running properly. Airflow ensures an adequate volume of air as recommended by the NFPA 33 safety guidelines. Also, it can detect when to change filters and meet relevant safety standards for the workforce and maintain quality results.

Types of Airflow in Paint Spray Booth

The airflow in the paint booth should be directed in a way that supports painting operations. Airflow characteristics primarily depend on booth design. Some classifications of airflow in paint designs are:

- Cross Draft Paint Booths (Horizontal Airflow)

The cross draft paint booths are popular in industries that manufacture smaller parts or assemblies. This design is characterized by horizontal airflow, when the air moves through the filtered front door and is exhaust through the rear. The filters trap the particles, and the filtered air is released into the environment via a pipe.

- Downdraft Paint Booths (Vertical Airflow)

The downdraft paint booths are characterized by vertical airflow that comes from the top and exhausts through the floor. This is an ideal car paint booth as it reduces contamination from dust & debris and overspraying.

- Modified Downdraft Paint Booths (Near Vertical Airflow)

These downdraft paint booths are characterized by air from the top of the booth to exhaust vents running alongside the base. It offers superior protection from contamination while eliminating the disadvantages related to traditional designs.

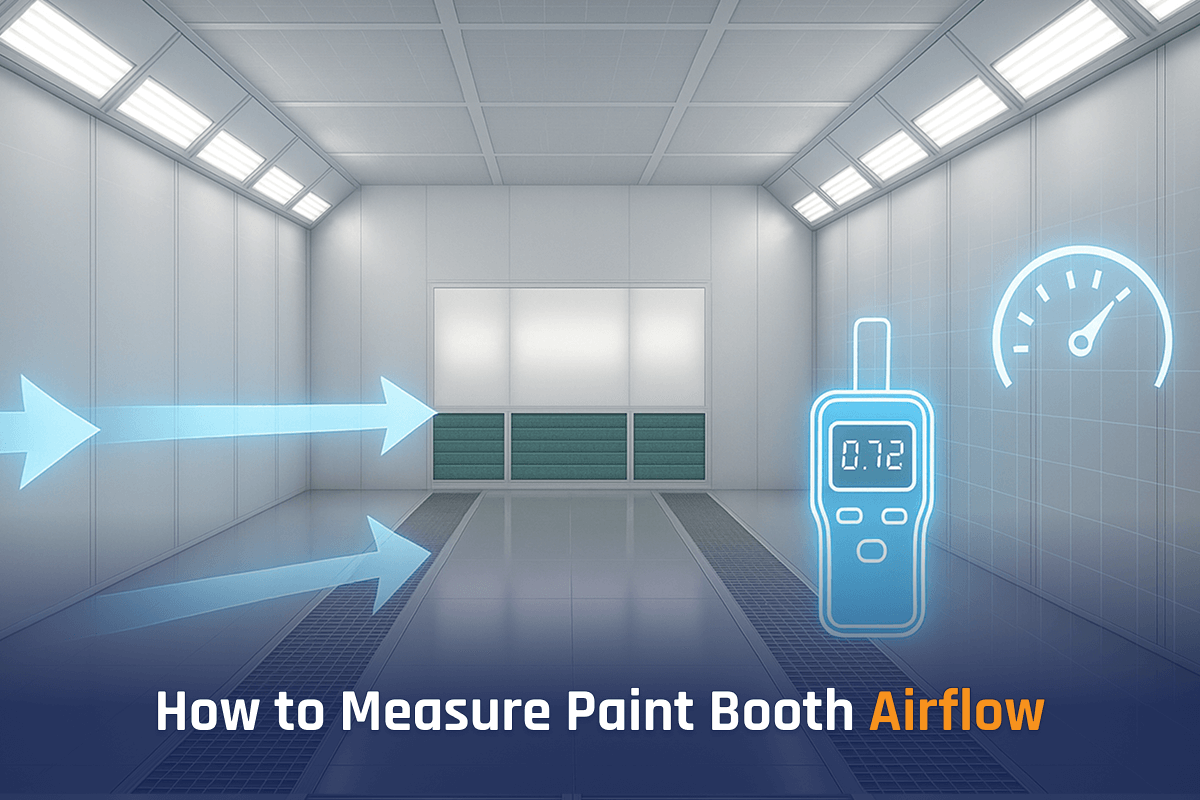

How to Measure Paint Booth Airflow

There are different types of tools and devices to measure paint spray booth airflow. The air flow is the air velocity that moves through filter face and is measured in feet per minute.

- Anemometer: The air travels through a moving vein that spins, and the tool calculates the reading.

- Digital Manometer: This tool measures the pressure differential, offering a pressure reading and mathematical equations to determine the air flow passing through the duct in cubic feet per minute.

- Velometer: This is a simple device that ensures proper ventilation in booths by measuring air velocity across the booths intake and exhaust and taking readings at each grid.

- Hot Wire: This is an excellent measuring method in which the air moves through a probe on the end. It calculates the area and offers accurate results.

The airflow significantly depends on the design of the paint booth. This is why we, at Sunstar Paint Booths & Auto Equipment, offer cutomized paint booth for sale Houston designed to meet your specific requirements. Our rich experience & technical expertise allow us to tailor solutions that offer value for money and promote efficient operations. For custom quotes, call us.